I've been working on this project for a good week now and though there isn't anything usable yet but I have eventually managed to demonstrate that its possible. I don't know if this has been done before so appoligies if it has. Also this is my first write up so bear with me.

As the topic suggests I've been building my own heatpipes. Eventually I might even make a heatsink with them.

Before I start I'll briefly explain how a heatpipes works, if you know/ aren't interested then skip this paragraph. Its a sealed pipewith a little volitile liquid in the bottom and nothing but the vapour of that liquid above. Depending on the liquid there will normally be at a mild vacuum as the liquid/vapour will balance at the pressure where its about to boil. Heating up the bottom where the liquid is will tip this balance so the liquid rapidly evapourates and raises the pressure so vapour at the other end condenses. These phase changes quickly cool the bottom and warm the top (it takes the same energy to evapourate 1 gram of water as to heat it by 540*C - phase change is very effective!). Commercial ones work in any orientataion but to keep them simple mine take heat from the bottom to the top. For more info go to wiki.

No its not acne - the sun went for me a few days ago

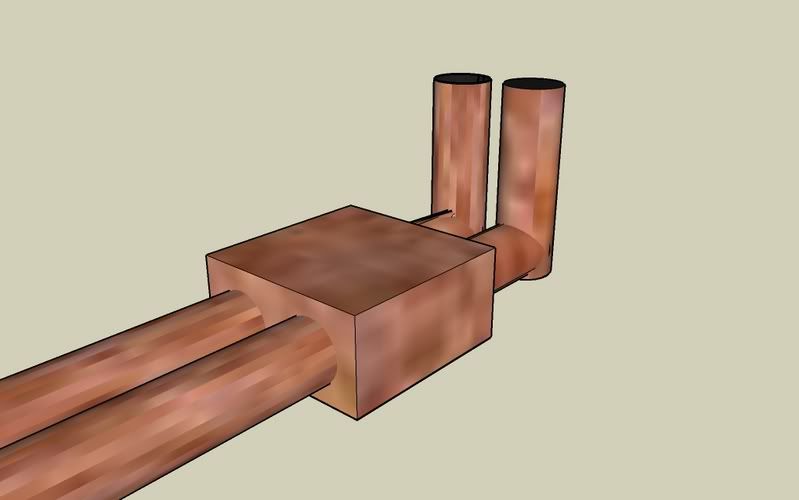

I wanted to know what would be most effective as a coolent, the most likely ones which are used commercially are ethanol and plain old water. So I made three - one with water, one with ethanol and one with just air as a comparison. To make them I took three equal lengths of copper pipe and squashed one end. This squashed end was soldered and tested (see above) and then a compression fitting was attached to the top. This was opened and the fluid (about 1.5ml) was put in. The fluid was then boiled until the air had been forced from the pipe when the compression fitting was quickly reassembled. As it cools the vacuum develops, then I shook them to ensure that there was some fluid left (you need very very little - it expands well over 1000 times when it vapourises).

Three finished pipes

Bottoms labled

I tested them today but I'll wait until tomorrow to post more. Build the suspense.

If you feel like copying then please do but beware that sealed pipes (among other things) are dangerous and can burst forcefuly enough to kill you.

Also sorry if this is the wrong board but its cooling related...

Reply With Quote

Reply With Quote